Values Miracom delivers Smart Factory Capabilities

Since 1998

Smart Factory Leader

in Korea

Beyond Korea,

Reaching out Worldwide

Smart Factory Experts

Chosen by Industry Leaders

World’s Best Smart Factory

Solution Provider

Why Miracom?

Why Miracom?

26 years of shaping

the future of manufacturing

-

- NO.1

-

World-proven Capabilities

We are the only Asian company to be listed

in Gartner's MES Magic Quadrant (MQ) Report,

winning recognition for our smart factory expertise and capabilities.

-

- 1,000professionals

-

No.1 Expert Group in South Korea

With the largest number of smart factory experts in Korea,

we are doing our best to satisfy our customers

by continuously conducting research and development to build optimal smart factories.

-

- 21industries

-

Extensive Industry Coverage

As our Best Practices (BPs) cover most industries

— 21 out of 25 — we can deliver industry-specific solutions

tailored to each customer.

20+

20+ countries

350+

350+ Domestic and overseas references

100,000+

100,000+ machines’ interfacing covered

700+

700+ types of machine interfaces applied

90 % *

The proportion of IT experts among employees*As of January, 2024

26+

26 years of experience

100+

More than 100 overseas factoriesMiracom’s Values

Miracom's advanced technology transforms factories

to accomplish the 4th Industrial Revolution and

manufacturing process automation/intelligence.

Factory connected

via a single platform

Collecting, analyzing, and sharing shop floor data in real time

allow the generation of a single set of goals

and improvement strategies which, in turn, leads to manufacturing productivity.

1

Smart factory

at a glance

Real-time monitoring of visualized management

and manufacturing status quo generates a visible factory operation system

that can promptly help customers identify problems and make decisions.

2

Profit-making Factory at optimal production sites

An optimal smart factory is made possible thanks

to the effective utilization of 4M enabled

by minimizing human variability and waste elements.

*4M : Man, Machine, Material, Method

3

Factory enabling autonomous and unmanned production

By applying the core technologies

of the 4th industrial revolution (AI, IoT, Digital Twin),

the autonomous factory is realized

through unmanned and intelligent manufacturing technologies.

4

Customer Success Stories

Global industry leaders

step up with Miracom

-

- Year 2022

- A domestic manufacturer of core materials for secondary batteries has applied Miracom's MES solution to all manufacturing plants nationwide since 2019, collecting equipment data by linking 44 machines and establishing an integrated management system by linking WMS and SAP to connect material input and shipment information. In particular, equipment-specific cycles, maintenance tasks, and tooling management functions tailored to the industry's characteristics have been incorporated, enabling lifecycle management and predictive maintenance capabilities for tooling and equipment. In addition, physical-based material location management and logistics movement minimization through smart factory have improved work efficiency.

- #MES #WMS #PLC

- Year 2022

- The customer, a global footwear manufacturing company, implemented MES for 31 manufacturing lines and built an integrated system that reflects the characteristics of the overseas shoe industry based on standard processes. The customer, which has increased productivity by establishing SCM production plan-based work/dispatch order management, set shoe management, and quality control functions, plans to spread smart factories to its second and new factories overseas based on its continuous trust relationship with Miracom.

- #SCM #MES

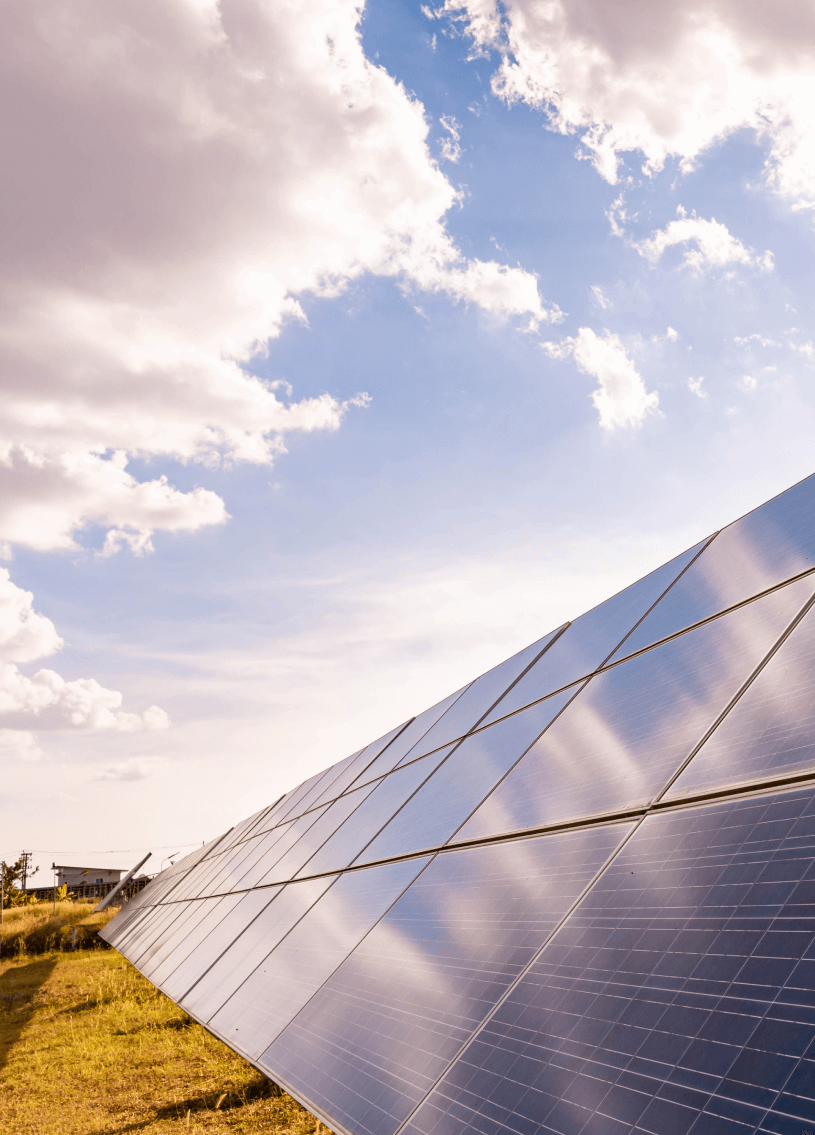

- Year 2022

- A company with the largest share of solar modules in the global market implemented factory automation and a high-speed data non-stop processing system to counter global factory labor shortage. The firm also set up a globally integrated control system for sending and combining distributed manufacturing data into the headquarters, enabling stable operation of factories around the world.

- #MES #EAI #Machine Automation

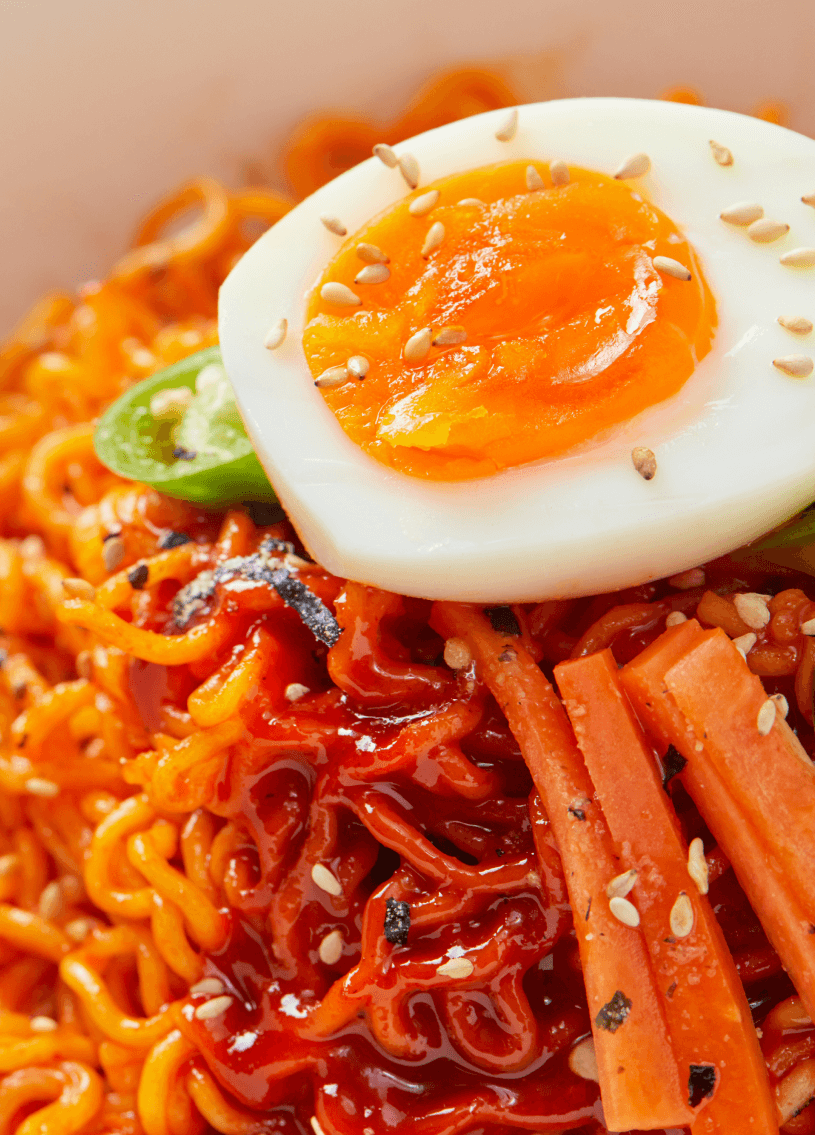

- Year 2022

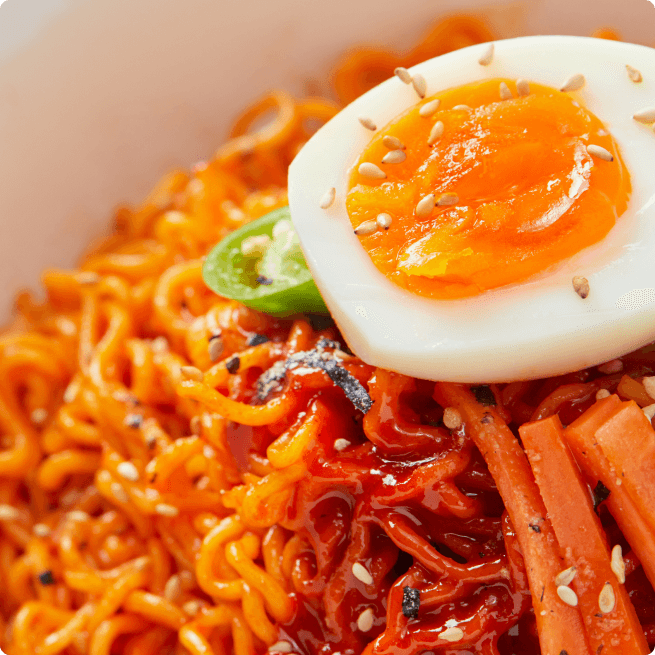

- A leading maker of Korean food, or K-food, built smart factory by applying MES and HACCP (food safety management certification) to the entire manufacturing process, including noodles, packaging, and soup. By linking data from more than 300 machines, the company established a recipe management and weighing automation system for noodle lines such as bagged noodles, containerized noodles, and dry noodles, soup mixing and packaging, and automated KPI (performance indicator) analysis, HACCP management, automated operation data collection, automatic calculation of process inspection efficiency, and inspection logs. Consequently, the firm could benefit from real-time inspection of defect tracking and cause analysis, which are the most crucial factors in the food industry. It also elevated their standing as a leader in the global food industry with rigorous safety management even for food exported overseas.

- #MES #QMS #MC #WMS #Logistics Automation

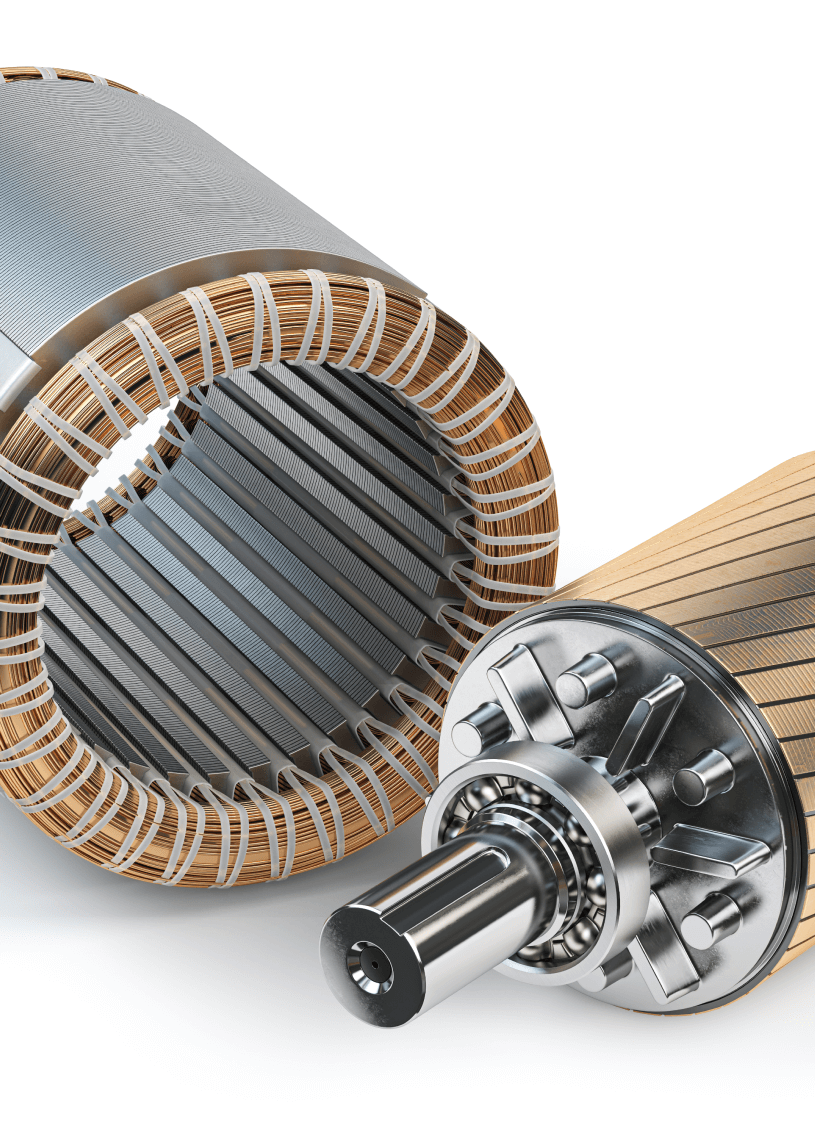

- Year 2021

- Miracom implemented an ERP system for a customer that produces reducers for precision control used in robotic arms, and through the interconnection between systems, they increased production by 30%, reduced defect rate by 70%, and achieved a 91% delivery compliance rate, and grew into a company that provides high-quality products.

- #MES #ERP

-