Industry Characteristics

In order to ensure the product stability of food and pharmaceuticals, compliance with HACCP (Hazard Analysis and Critical Control Point) and GMP (Good Manufacturing Practice) regulations is essential. Maintaining uniform quality levels with past manufacturing methods that rely on worker proficiency is a challenge. What's more, it is necessary to comply with safety standards and respond to increasing regulations by tracking and managing manufacturing history from raw materials to finished products. To overcome these difficulties and ensure stability and quality, smart manufacturing process management that standardizes the process from 「raw material input to formulation/processing, packaging/shipping, and transportation」 and automatically aggregates and analyzes process/quality/facility data is required. Especially when considering smart factory implementation from the planning stages of building a new facility, it becomes easier to achieve productivity enhancement and ensure visibility through automation.

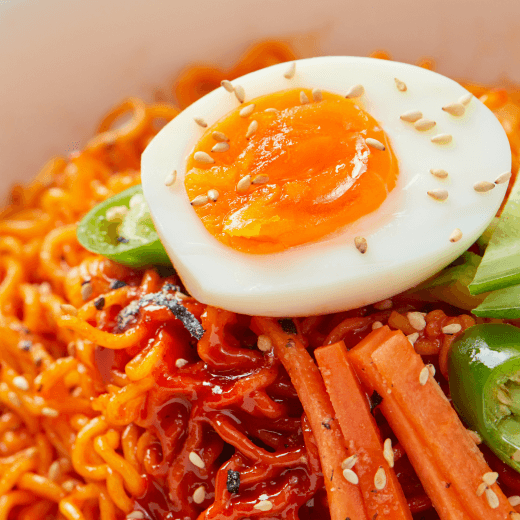

A leading maker of Korean food, or K-food, built smart factory by applying MES and HACCP (food safety management certification) to the entire manufacturing process, including noodles, packaging, and soup. By linking data from more than 300 machines, the company established a recipe management and weighing automation system for noodle lines such as bagged noodles, containerized noodles, and dry noodles, soup mixing and packaging, and automated KPI (performance indicator) analysis, HACCP management, automated operation data collection, automatic calculation of process inspection efficiency, and inspection logs. Consequently, the firm could benefit from real-time inspection of defect tracking and cause analysis, which are the most crucial factors in the food industry. It also elevated their standing as a leader in the global food industry with rigorous safety management even for food exported overseas.

A leading maker of Korean food, or K-food, built smart factory by applying MES and HACCP (food safety management certification) to the entire manufacturing process, including noodles, packaging, and soup. By linking data from more than 300 machines, the company established a recipe management and weighing automation system for noodle lines such as bagged noodles, containerized noodles, and dry noodles, soup mixing and packaging, and automated KPI (performance indicator) analysis, HACCP management, automated operation data collection, automatic calculation of process inspection efficiency, and inspection logs. Consequently, the firm could benefit from real-time inspection of defect tracking and cause analysis, which are the most crucial factors in the food industry. It also elevated their standing as a leader in the global food industry with rigorous safety management even for food exported overseas.

South Korea’s leading maker of coffee and other beverages needed to improve and streamline their manufacturing process as their product offerings widened so as to cater to consumers' diversifying tastes. They also sought to maintain quality without relying on skilled workers. To this end, Miracom established a production management system (MES), equipment management system, energy management system, and integrated operation system at the factory in Region B to integrate process steps that were operated individually and enabled automatic control and real-time monitoring. Subsequently, as the company expanded its operations to the region C, this was further enhanced to allow the system — rather than humans — to make decisions regarding process advancements based on information such as production plans, equipment status, and inventory levels. With establishment of an integrated automated operation and control system by synchronizing the MES system and manufacturing/utility equipment, Miracom was able to establish a system that responds to issues at the manufacturing site in real time and increase productivity by optimizing the timing and quantity of production based on demand forecasting.

South Korea’s leading maker of coffee and other beverages needed to improve and streamline their manufacturing process as their product offerings widened so as to cater to consumers' diversifying tastes. They also sought to maintain quality without relying on skilled workers. To this end, Miracom established a production management system (MES), equipment management system, energy management system, and integrated operation system at the factory in Region B to integrate process steps that were operated individually and enabled automatic control and real-time monitoring. Subsequently, as the company expanded its operations to the region C, this was further enhanced to allow the system — rather than humans — to make decisions regarding process advancements based on information such as production plans, equipment status, and inventory levels. With establishment of an integrated automated operation and control system by synchronizing the MES system and manufacturing/utility equipment, Miracom was able to establish a system that responds to issues at the manufacturing site in real time and increase productivity by optimizing the timing and quantity of production based on demand forecasting.

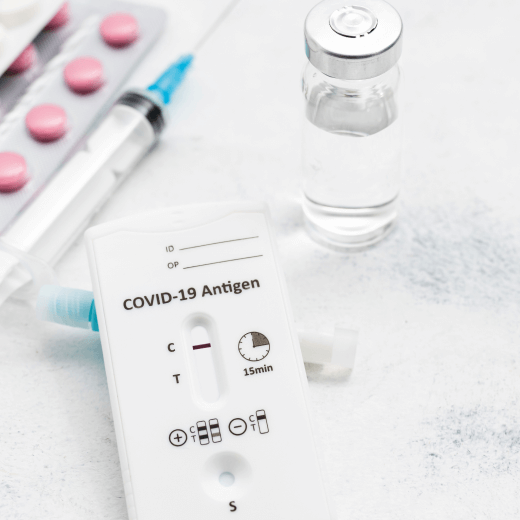

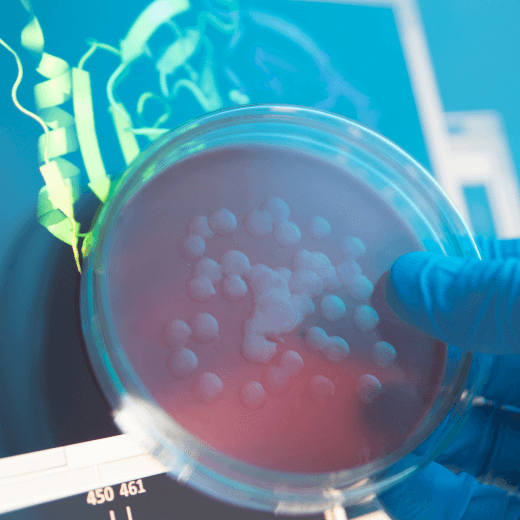

A multiplex molecular diagnostics kit maker had manufacturing execution system(MES) implemented through process innovation in the production sector. Miracom established a real-time production management system to meet GMP regulations, collected important raw data in real time, and deployed efficient on-site work management by applying CSV (Computer system Validation). Through the process, Miracom established and utilized MES for the first time in the diagnostic kit manufacturing area.

A multiplex molecular diagnostics kit maker had manufacturing execution system(MES) implemented through process innovation in the production sector. Miracom established a real-time production management system to meet GMP regulations, collected important raw data in real time, and deployed efficient on-site work management by applying CSV (Computer system Validation). Through the process, Miracom established and utilized MES for the first time in the diagnostic kit manufacturing area.

Miracom built an automated infrastructure for a client to collect production, quality, and equipment information. The client has been researching serum-free media for 30 years, and established an integrated manufacturing monitoring system to ensure real-time manufacturing visibility. As a result, they benefited from a sharp reduction in data collection time and improved work efficiency by quickly identifying the current situation. They are continuously working with Miracom on improvements to build a smart factory in stages.

Miracom built an automated infrastructure for a client to collect production, quality, and equipment information. The client has been researching serum-free media for 30 years, and established an integrated manufacturing monitoring system to ensure real-time manufacturing visibility. As a result, they benefited from a sharp reduction in data collection time and improved work efficiency by quickly identifying the current situation. They are continuously working with Miracom on improvements to build a smart factory in stages.