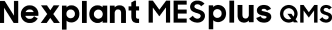

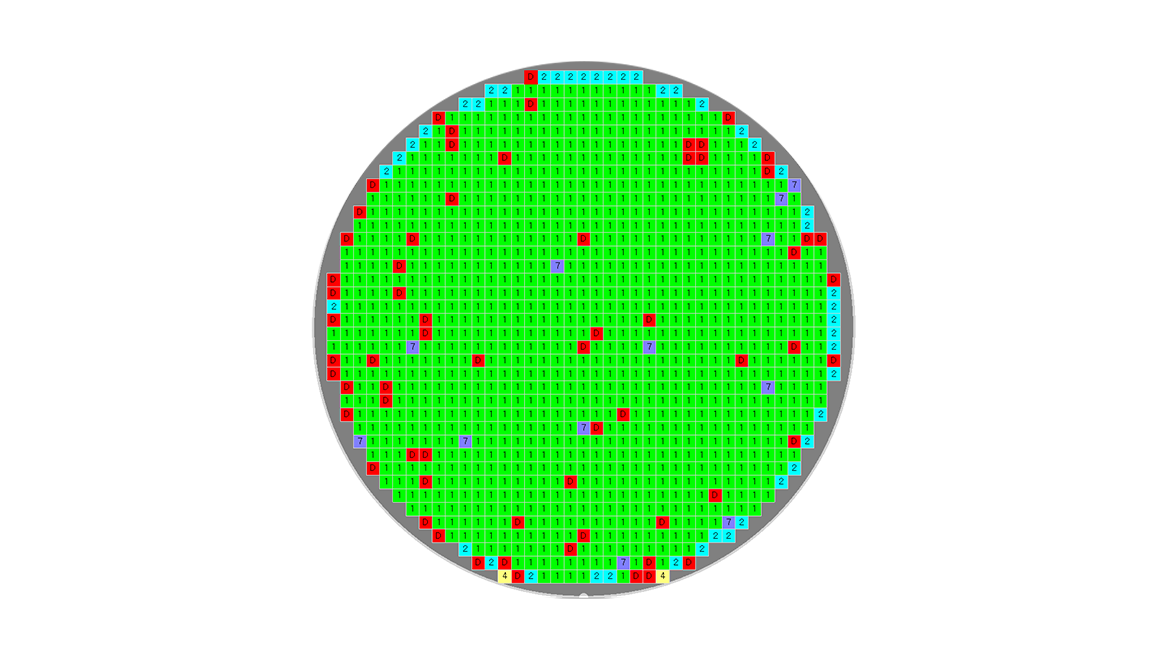

A specialized semiconductor testing company was challenged to secure high production quality to satisfy customer's demands not affected by increasing production volumes.

Therefore, Miracom deployed semiconductor-specific MES and added QMS function to the system. The QMS allowed for analysis of yields as per process and management of inspection data as per process/order.

Based on our accumulated experience in the semiconductor industry, Miracom built a statistical analytics and automation systems for the semiconductor test line of the firm who became so pleased that they gave Miracom new extra orders after the end customer’s approval of quality audit.

approving the solution provider's solution quality.

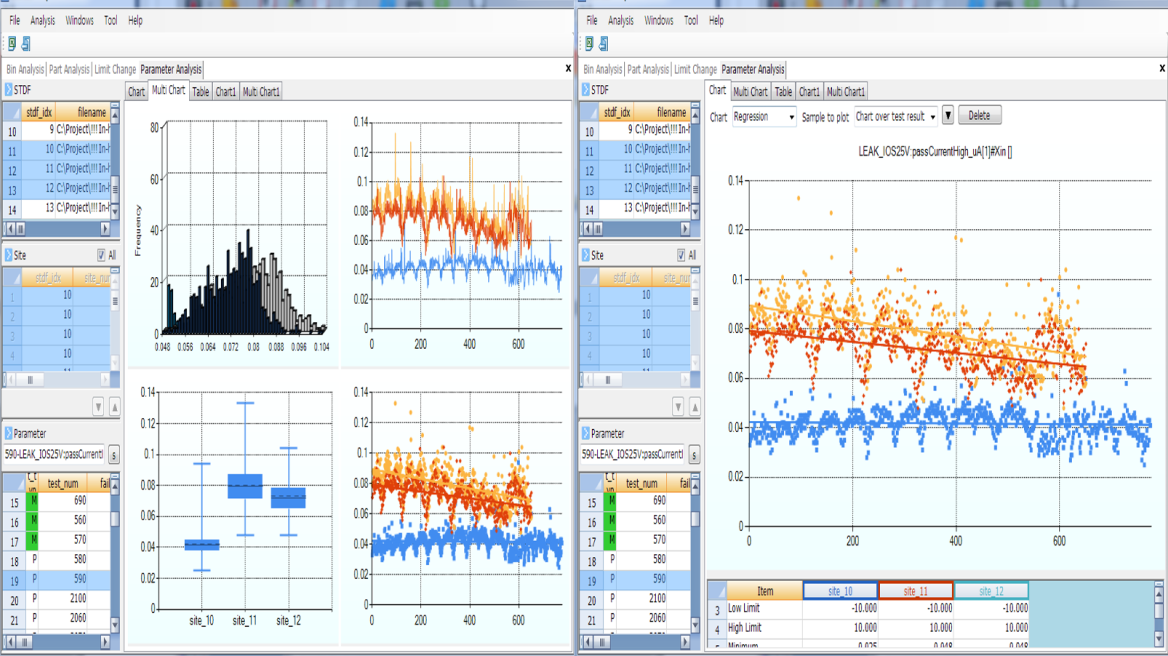

An electronics manufacturing company who produces a wide range of products requested Miracom to help them to cope with increasing diversity of production. By adopting Miracom's QMS solution, the company managed component quality from the initial stage by controlling raw material quality abnormalities, and created a system to analyze the source of manufacturing defects in real-time based on data with a detailed quality analytics and tracking system. In addition, by linking QMS and ERP to build a DT-based smart factory that integrates import inspection results, the company was able to increase quality competitiveness by optimizing process conditions beyond the quality threshold.

An electronics manufacturing company who produces a wide range of products requested Miracom to help them to cope with increasing diversity of production. By adopting Miracom's QMS solution, the company managed component quality from the initial stage by controlling raw material quality abnormalities, and created a system to analyze the source of manufacturing defects in real-time based on data with a detailed quality analytics and tracking system. In addition, by linking QMS and ERP to build a DT-based smart factory that integrates import inspection results, the company was able to increase quality competitiveness by optimizing process conditions beyond the quality threshold.

A specialized semiconductor testing company was challenged to secure high production quality to satisfy customer's demands not affected by increasing production volumes.

Therefore, Miracom deployed semiconductor-specific MES and added QMS function to the system. The QMS allowed for analysis of yields as per process and management of inspection data as per process/order.

Based on our accumulated experience in the semiconductor industry, Miracom built a statistical analytics and automation systems for the semiconductor test line of the firm who became so pleased that they gave Miracom new extra orders after the end customer’s approval of quality audit.

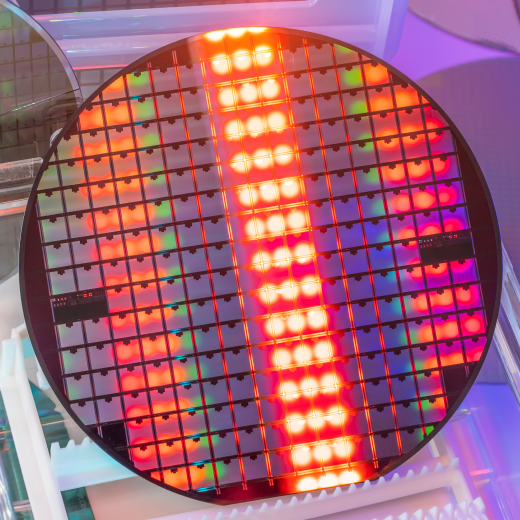

A specialized semiconductor testing company was challenged to secure high production quality to satisfy customer's demands not affected by increasing production volumes.

Therefore, Miracom deployed semiconductor-specific MES and added QMS function to the system. The QMS allowed for analysis of yields as per process and management of inspection data as per process/order.

Based on our accumulated experience in the semiconductor industry, Miracom built a statistical analytics and automation systems for the semiconductor test line of the firm who became so pleased that they gave Miracom new extra orders after the end customer’s approval of quality audit. A wholesome food company came across increasing quality risks due to an inadequate enterprise-wide quality management system. To meet a need to upgrade the standardized proactive quality management system, they adopted Miracom's QMS to manage quality in all processes from product development to shipment. By issuing inspection orders, implementing a tracking management system, and analyzing the types and causes of nonconforming products, they gained a thorough quality management system. This helped them establish their position as a leading company in the Food and Beverage (F&B) industry.

A wholesome food company came across increasing quality risks due to an inadequate enterprise-wide quality management system. To meet a need to upgrade the standardized proactive quality management system, they adopted Miracom's QMS to manage quality in all processes from product development to shipment. By issuing inspection orders, implementing a tracking management system, and analyzing the types and causes of nonconforming products, they gained a thorough quality management system. This helped them establish their position as a leading company in the Food and Beverage (F&B) industry.