Service Overview

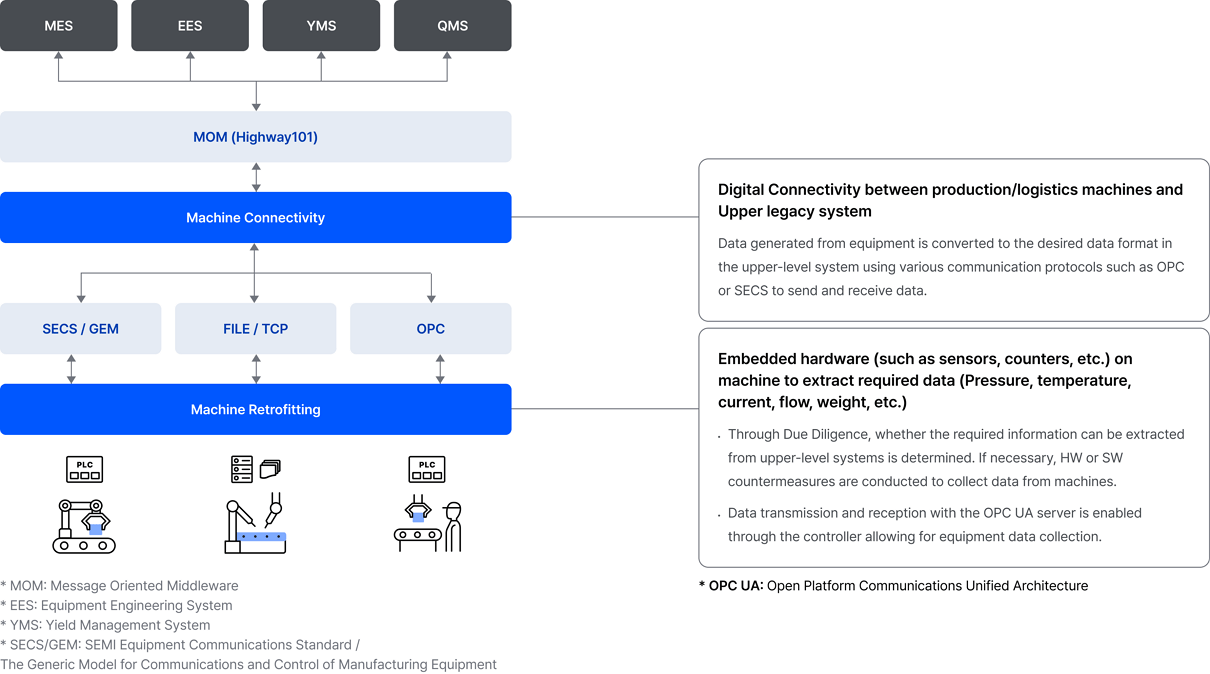

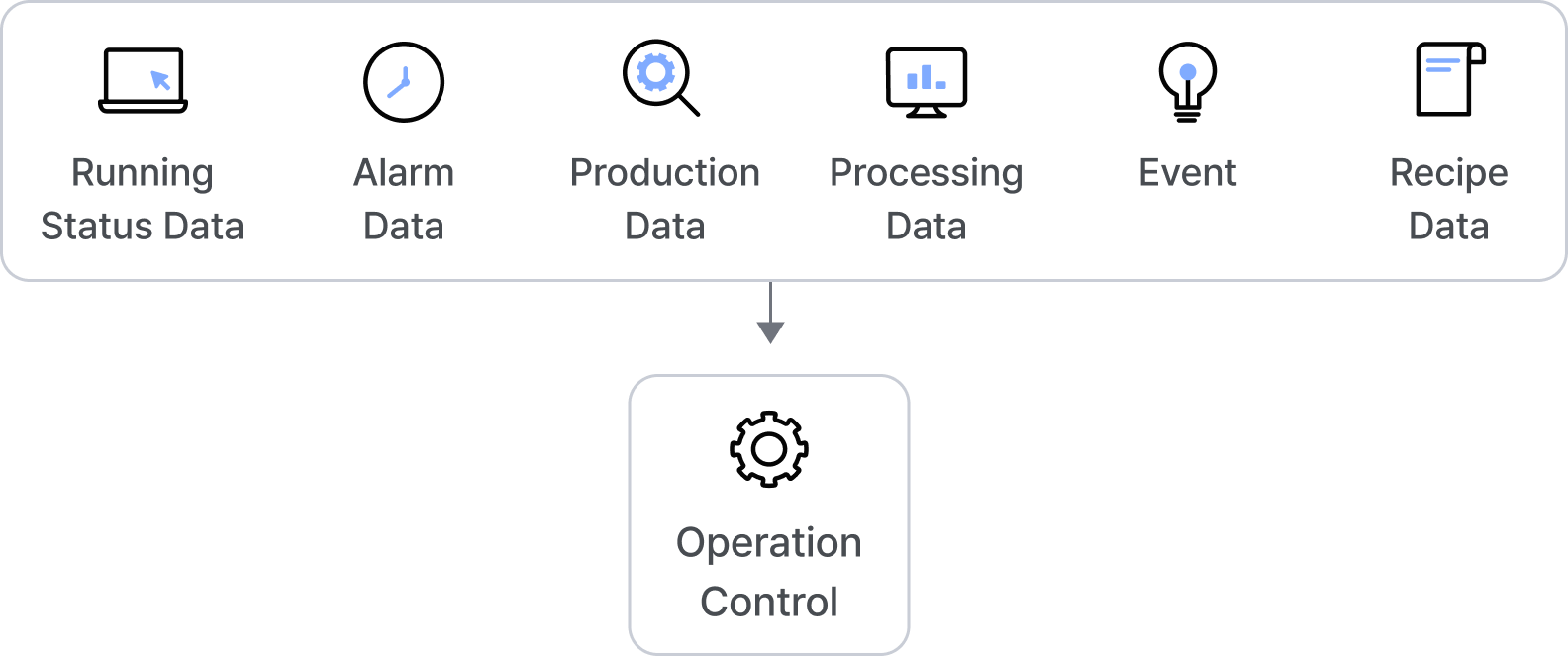

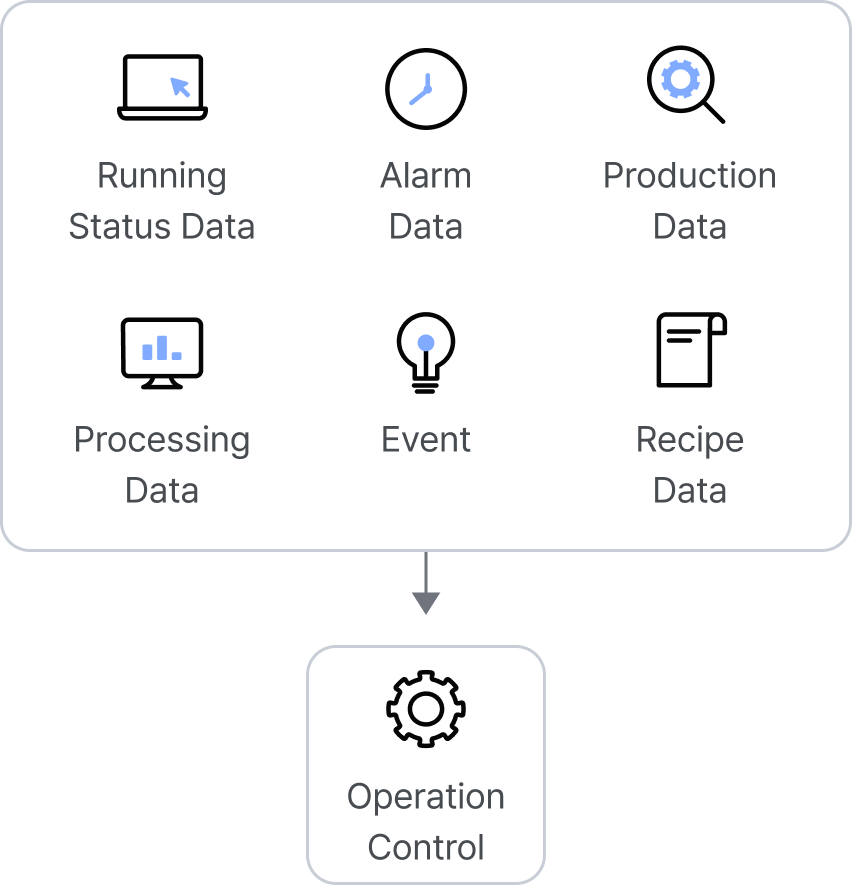

To realize a smart factory, it is necessary to collect data from machines in real time and control machines according to the occurrence of events.

Miracom converts customer's manufacturing site into an automated environment where data flows by retrofitting machines and connecting machines via machine interfaces.

- MOM(Highway101)

- MES

- EES

- YMS

- QMS

- I/F (MC)

- SECS/GEM

- FILE/TCP

- OPC

- Machine Retrofitting

- Digital Connectivity between production/logistics machines and Upper legacy system

- Data generated from equipment is converted to the desired data format in the upper-level system using various communication protocols such as OPC or SECS to send and receive data.

- Embedded hardware (such as sensors, counters, etc.) on machine to extract required data (Pressure, temperature, current, flow, weight, etc.)

- Through Due Diligence, whether the required information can be extracted from upper-level systems is determined. If necessary, HW or SW countermeasures are conducted to collect data from machines.

- Data transmission and reception with the OPC UA server is enabled through the controller allowing for equipment data collection.

- *OPC UA : Open Platform Communications Unified Architecture

- * MOM : Message Oriented Middleware

- * EES : Equipment Engineering System

- * YMS : Yield Management System

- * SECS/GEM : SEMI Equipment Communications Standard / The Generic Model for Communications and Control of Manufacturing Equipment

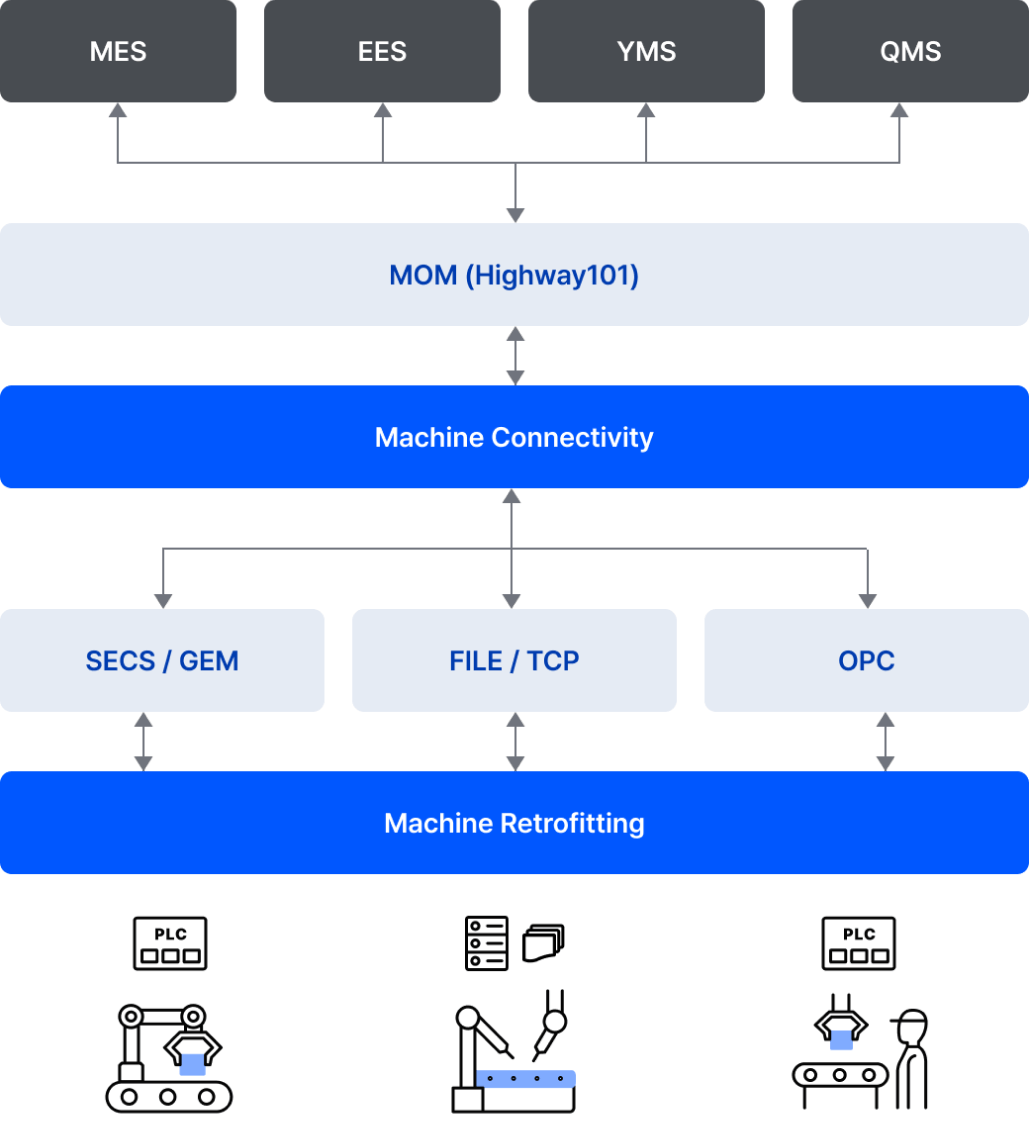

- MOM(Highway101)

- MES

- EES

- YMS

- QMS

- I/F (MC)

- SECS/GEM

- FILE/TCP

- OPC

- Machine Retrofitting

-

- Digital Connectivity between production/logistics machines and Upper legacy system

- Data generated from equipment is converted to the desired data format in the upper-level system using various communication protocols such as OPC or SECS to send and receive data.

-

- Embedded hardware (such as sensors, counters, etc.) on machine to extract required data (Pressure, temperature, current, flow, weight, etc.)

- Through Due Diligence, whether the required information can be extracted from upper-level systems is determined. If necessary, HW or SW countermeasures are conducted to collect data from machines.

- Data transmission and reception with the OPC UA server is enabled through the controller allowing for equipment data collection.

* OPC UA: Open Platform Communications Unified Architecture

* EES: Equipment Engineering System

* YMS: Yield Management System

* SECS/GEM: SEMI Equipment Communications Standard / The Generic Model for Communications and Control of Manufacturing Equipment

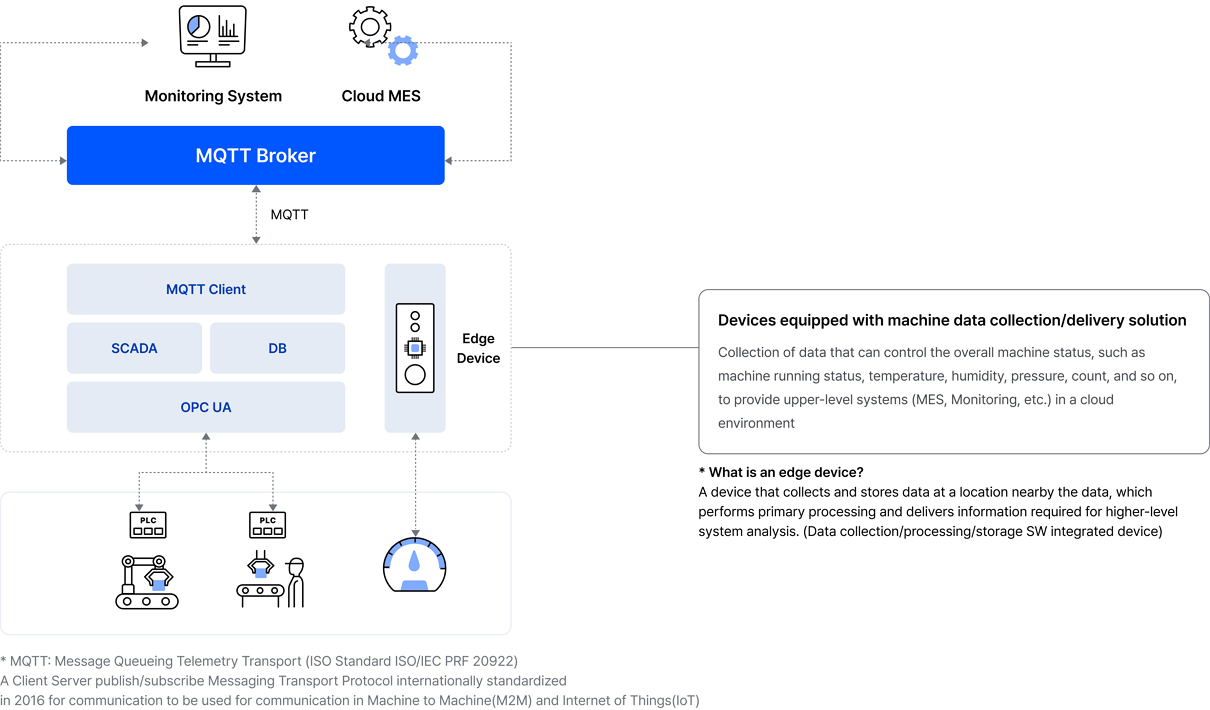

"Cloud-based machine connectivity through Edge Device" helps clients easily collect, connect, and utilize machine data in the cloud environment.

- MQTT Broker

- Monitoring System

- Cloud MES

- Edge Device

- MQTT Client

- SCADA

- DB

- OPC UA

- Devices equipped with machine data collection/delivery solution

-

Collection of data that can control the overall machine status, such as machine running status, temperature, humidity, pressure, count, and so on, to provide upper-level systems (MES, Monitoring, etc.) in a cloud environment

* What is an edge device? A device that collects and stores data at a location nearby the data, which performs primary processing and delivers information required for higher-level system analysis. (Data collection/processing/storage SW integrated device)

- * MQTT : Message Queueing Telemetry Transport (ISO Standard ISO/IEC PRF 20922) A Client Server publish/subscribe Messaging Transport Protocol internationally standardized in 2016 for communication to be used for communication in Machine to Machine(M2M) and Internet of Things(IoT)

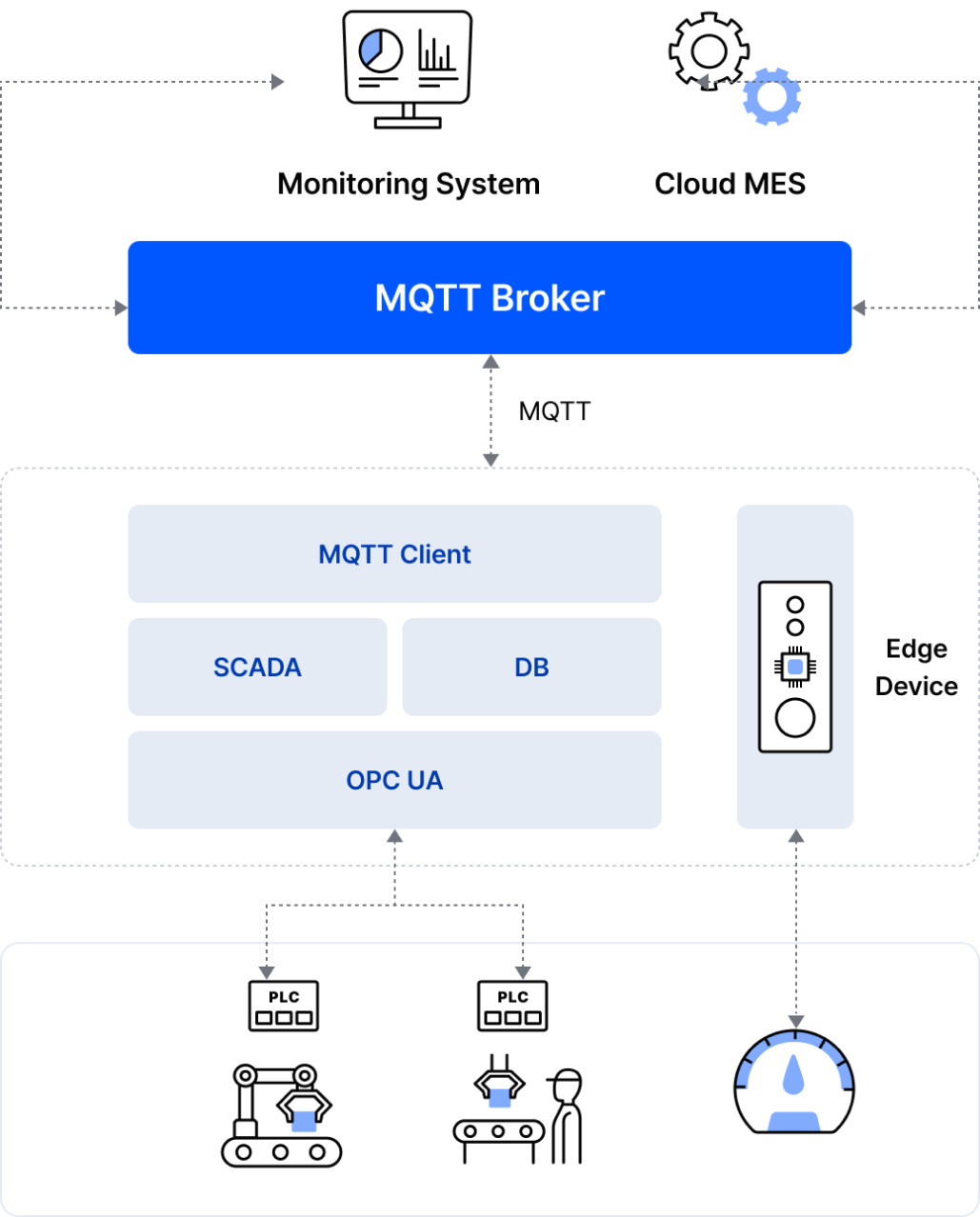

- MQTT Broker

- Monitoring System

- Cloud MES

- Edge Device

- MQTT Client

- SCADA

- DB

- OPC UA

-

- Devices equipped with machine data collection/delivery solution

-

Collection of data that can control the overall machine status, such as machine running status, temperature, humidity, pressure, count, and so on, to provide upper-level systems (MES, Monitoring, etc.) in a cloud environment

* What is an edge device?

A device that collects and stores data at a location nearby the data, which performs primary processing and delivers information required for higher-level system analysis. (Data collection/processing/storage SW integrated device)

* MQTT: Message Queueing Telemetry Transport (ISO Standard ISO/IEC PRF 20922) A Client Server publish/subscribe Messaging Transport Protocol internationally standardized in 2016 for communication to be used for communication in Machine to Machine(M2M) and Internet of Things(IoT)

A manufacturer of solar cells and modules encountered the problem of difficulties in integrated control while spreading global factories and needed to establish a system that facilitates remote management by multiple users. To introduce an effective system, Miracom built a comprehensive automated control system based on high-tech BP practices. Miracom developed a multi-FAB remote monitoring and control system capable of processing large amounts of data at ultra-high speeds and a real-time machine control system that standardized interfaces for each equipment model to enable integrated control of domestic and overseas plants. This enabled remote response by domestic experts in case of problems and reduced management costs by half.

A manufacturer of solar cells and modules encountered the problem of difficulties in integrated control while spreading global factories and needed to establish a system that facilitates remote management by multiple users. To introduce an effective system, Miracom built a comprehensive automated control system based on high-tech BP practices. Miracom developed a multi-FAB remote monitoring and control system capable of processing large amounts of data at ultra-high speeds and a real-time machine control system that standardized interfaces for each equipment model to enable integrated control of domestic and overseas plants. This enabled remote response by domestic experts in case of problems and reduced management costs by half.

An electronics manufacturer advanced its existing MES by adding machine automation and manufacturing intelligence functions to secure competitiveness backed by production data. The company established a raw material shipment data and machine data analysis system, built an integrated operation system connected to ERP. They also applied a visualized real-time monitoring report function. As a result, the response time in case of abnormalities was reduced by 50% compared to the previous one, and the machine utilization rate was improved by 10%.

An electronics manufacturer advanced its existing MES by adding machine automation and manufacturing intelligence functions to secure competitiveness backed by production data. The company established a raw material shipment data and machine data analysis system, built an integrated operation system connected to ERP. They also applied a visualized real-time monitoring report function. As a result, the response time in case of abnormalities was reduced by 50% compared to the previous one, and the machine utilization rate was improved by 10%.

A semiconductor packaging and testing company applied Miracom's Machine Control solution(Which enables machine connectivity) to the entire semiconductor post-processing process to implement equipment interfaces and automation based on standards set by the SEMI Association. The company also implemented interfaces with host systems such as BOM and lot tracking to improve productivity based on reliable equipment information.

A semiconductor packaging and testing company applied Miracom's Machine Control solution(Which enables machine connectivity) to the entire semiconductor post-processing process to implement equipment interfaces and automation based on standards set by the SEMI Association. The company also implemented interfaces with host systems such as BOM and lot tracking to improve productivity based on reliable equipment information.

The customer, which came in third to develop the world's industrial synthetic diamond, applied Miracom's MES and MC solutions as it promoted the expansion of MES to

overseas factories. Through machine automation, the firm could minimize inefficiencies caused by manual work and improve production quality and efficiency by implementing

a system that enables traceability between factories. In particular, by configuring an integrated dashboard for domestic and overseas factories, real-time machine operation status

analytics was made possible, enabling more efficient management of manufacturing sites.

The customer, which came in third to develop the world's industrial synthetic diamond, applied Miracom's MES and MC solutions as it promoted the expansion of MES to

overseas factories. Through machine automation, the firm could minimize inefficiencies caused by manual work and improve production quality and efficiency by implementing

a system that enables traceability between factories. In particular, by configuring an integrated dashboard for domestic and overseas factories, real-time machine operation status

analytics was made possible, enabling more efficient management of manufacturing sites.