Industry Characteristics

The machinery and metal industry has been utilizing systems mainly for production performance management at the POP* level, but with the increase in production varieties and process complexity, the adoption of smart factories for real-time manufacturing execution management is gaining momentum. To increase the productivity of manufacturing and assembling parts through material processing — casting/forging/cutting, molding, heat treatment, etc. — data from the entire process ranging from design quality management, work order management, production quality management, and work-in-process/inventory management to logistics management are interconnected to share real-time information and visualize the manufacturing site to increase equipment utilization and respond quickly to issues.

* POP: Point of Production Data Management

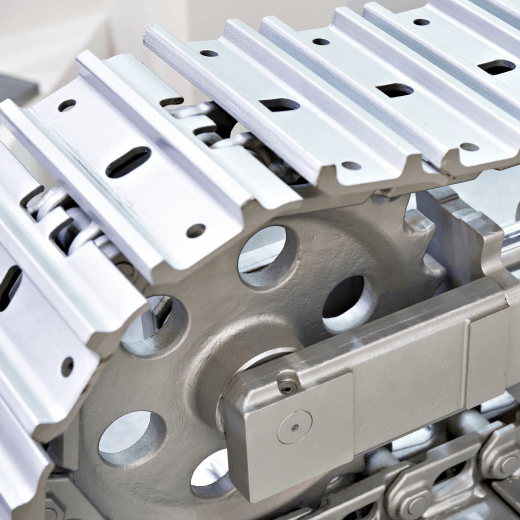

An aluminum parts company had a difficulty manually managing data in the field. To address the situation, Miracom's MES was implemented to secure traceability with lot Tracking management and lay the foundation for data collection for production and quality information collection. Consequently, it reduced human error, increased production/quality traceability, slashed quality tracking time by 80%, and manual work by 75%.

An aluminum parts company had a difficulty manually managing data in the field. To address the situation, Miracom's MES was implemented to secure traceability with lot Tracking management and lay the foundation for data collection for production and quality information collection. Consequently, it reduced human error, increased production/quality traceability, slashed quality tracking time by 80%, and manual work by 75%.

A construction heavy equipment parts maker had been manually managing field data resulting in undermined efficiency due to limited production/quality information management capability. To address this problem, Miracom established a system to manage and monitor the production line in real time by collecting detailed process track records and machine downtime status. Through rigorous tracking of process working hours, equipment, workers, and raw materials, the firm has secured traceability to solve the root of the problem in the event of defective products and created a high-quality production environment.

A construction heavy equipment parts maker had been manually managing field data resulting in undermined efficiency due to limited production/quality information management capability. To address this problem, Miracom established a system to manage and monitor the production line in real time by collecting detailed process track records and machine downtime status. Through rigorous tracking of process working hours, equipment, workers, and raw materials, the firm has secured traceability to solve the root of the problem in the event of defective products and created a high-quality production environment.

South Korea's number one refractory maker pushed ahead with the conversion to a smart factory to integrate and manage multiple factories in various regions of Korea. So as to create a centralized maintenance system, a system based on a standard platform was configured across the factories. Miracom conducted integrated deployment and synchronization monitoring. By monitoring key production and quality KPIs in real time, investment costs for maintenance were minimized, and management costs were reduced by 60%.

South Korea's number one refractory maker pushed ahead with the conversion to a smart factory to integrate and manage multiple factories in various regions of Korea. So as to create a centralized maintenance system, a system based on a standard platform was configured across the factories. Miracom conducted integrated deployment and synchronization monitoring. By monitoring key production and quality KPIs in real time, investment costs for maintenance were minimized, and management costs were reduced by 60%.

A bottle cap manufacturer had difficulty making reliable system-based decisions by managing data manually. Miracom's smart factory consultants defined the direction of the smart factory through thorough process/system analysis and VoC listening and established an integrated production system that maximizes manufacturing competitiveness through a pre-prediction and verification system that organically utilizes the customer's manufacturing resources. In addition, by collecting data from facilities, Miracom identified the cause of abnormalities in facilities based on the data, and monitored the operation status to secure an uninterrupted production system.

A bottle cap manufacturer had difficulty making reliable system-based decisions by managing data manually. Miracom's smart factory consultants defined the direction of the smart factory through thorough process/system analysis and VoC listening and established an integrated production system that maximizes manufacturing competitiveness through a pre-prediction and verification system that organically utilizes the customer's manufacturing resources. In addition, by collecting data from facilities, Miracom identified the cause of abnormalities in facilities based on the data, and monitored the operation status to secure an uninterrupted production system.